Modern technology, such as 3D and AI, offer new, groundbreaking possibilities for how products can be designed and produced, as well as how they are experienced by customers. During 2020, H&M Group explored tech initiatives spreading from digital avatars to virtual fitting rooms – as well as 3D-based design that eliminates waste.

News Article

Taking sustainable fashion to a new level with tech

Watch how 3D technology can be one of the next gamechangers for circular fashion.

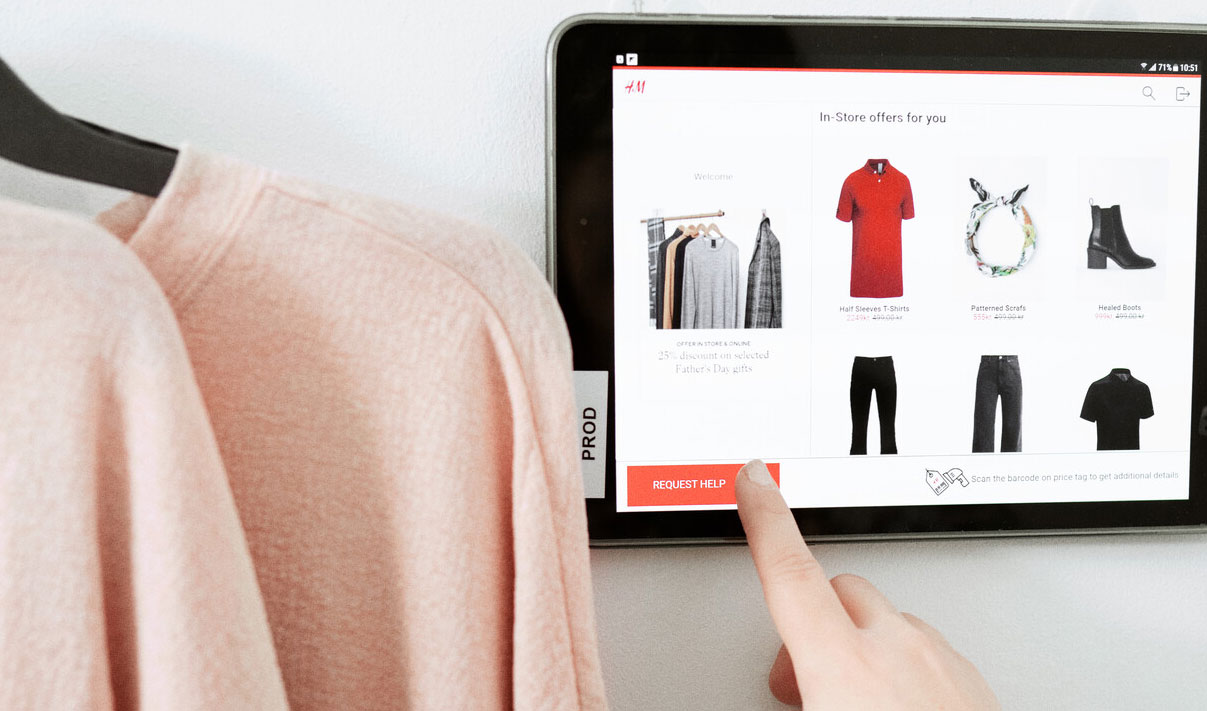

New technology opens up for totally new ways to engage with customers. One exciting example that H&M Group delved into in its internal innovation lab, is a personal avatar that helps customers try on clothes in virtual fittings. Besides making it possible to add another dimension to the shopping experience, virtual fittings could also help to improve accessibility and reduce product returns.

“By creating digital twins of our products, customers can try on clothes virtually”, says Frans Borgstrand, who is working with developing 3D technology at H&M Group. “And, if these virtual try-ons are based on individual measurements, for example from a digital body scan, the customer is more likely to find the ultimate size of a garment”.

By creating digital twins of our products, customers can try on clothes virtually to find the ultimate size of garment.

Frans Borgstrand is working with developing 3D technology at H&M Group.

Today, around 50% of H&M Group’s returns are based on size and fit not meeting customer expectations. “With the help of technology and this way of trying and experiencing products before deciding on a purchase, the number of returns could be reduced extensively in the future”, says Frans Borgstrand.

New tech solutions can also help to better match demand and supply. During 2020, H&M Group launched the AI tool Movebox, an algorithm that enables redistribution of products to locations where there is demand. Looking ahead, using this algorithm will also make it possible to react faster to changes in customer preferences, which will lead to a decrease in over production.

Saving material with 3D technology

But innovative technology can also be an excellent tool in the shift to a more circular fashion industry – for example, in the design stage. Moving away from designing a product using traditional sketches and physical samples to using 3D-based design production, can greatly reduce fabric waste.

To explore exactly how waste can be eliminated from the design process, the design team at H&M used 3D technology and zero waste pattern cutting techniques in the making of the Zero Waste Dress, which was launched in May 2020. The design team was inspired by the traditional way of making kimonos, which included not wasting any precious fabric.

By adjusting colour, shape and structure using 3D design, precious material is being saved.

The H&M dress was developed using zero waste pattern cutting techniques.

Today, far too much fabric is used to create prototypes in the initial stage of the design process. Using 3D technology dramatically cuts down the usage of that kind of material.

Recycled polyester was used to make the dress and instead of making several traditional prototypes before starting the production, the team adjusted colour, shape and structure using 3D technology. This allowed the team to reduce the number of samples during the design process, which saved a great amount of material. “Today, far too much fabric is used to create prototypes in the initial stage of the design process. Using 3D technology dramatically cuts down the usage of that kind of material”, says Frans Borgstrand.

According to Reverse Resources, there are roughly 4-5 million tonnes of cutting scraps generated globally each year. In the making of the Zero Waste Dress, the team combined the use of 3D design tools and zero waste pattern cutting techniques to eliminate the fabric scraps from the cutting tables, saving a lot of precious resources.

Read more:

Download the full Sustainability Performance Report 2020.